ThunderCoat is made in the USA through an in-line galvanizing process that provides a heavy, triple-layer of zinc protection against corrosion ─ plus a durable top coat to seal the surface. The interior is also sealed with baked-on zinc coating, leaving no bare metal. ThunderCoat can be welded on-site, and if damaged, its coating can easily be repaired using cold galvanizing products. Each piece is custom crafted to minimize scrap or drop, and eliminate the extra costs associated with after-fabrication post hot-dip galvanizing. Rely on ThunderCoat’s superior corrosion protection for solar, greenhouse, metal buildings or fabric structures, farmstead and dairy applications.

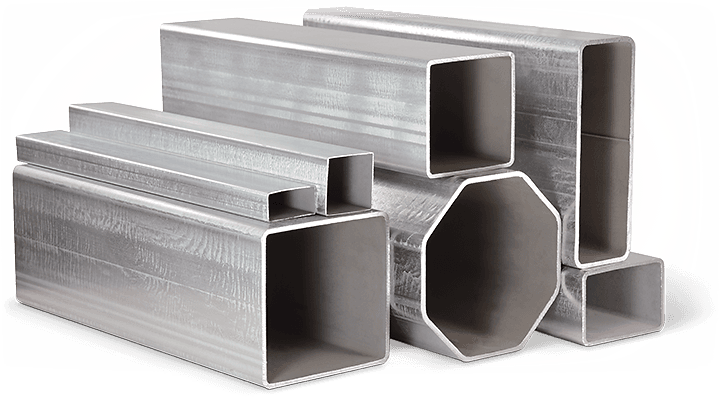

We produce our mechanical tubing in accordance with ASTM A500 specifications and using our in-house galvanizing process in compliance with ASTM A1057 coating requirements. Shapes and sizes include: