The difference between SureThread CW Pipe & Import ERW Pipe

When it comes to standard pipe (and really any steel pipe or tube product), there’s always a question of quality when comparing domestic and import products. At Wheatland Tube, we’re committed to manufacturing the highest quality products, including our SureThreadTM continuous weld (CW) standard pipe. That’s why we’ve set out to educate pipe consumers (distributors and contractors) about the differences between our CW pipe and import ERW pipe, specifically when referring to the smaller diameters of ½” to 2”.

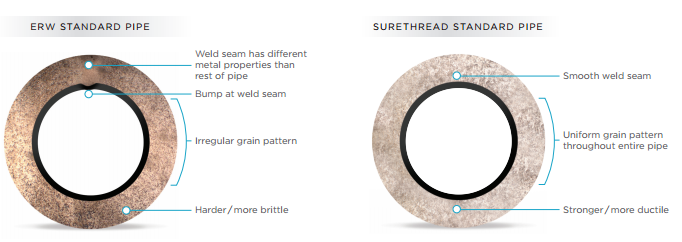

Made to ASTM A53 Type F Grade A specifications, SureThreadTM CW pipe is easier to work with than import ERW pipe because of its uniform grain structure. This makes it easier to bend, cut and thread.

The difference in quality all begins with how the pipe is manufactured.

Where import ERW pipe is cold-formed, SureThread is hot-formed. Throughout the process of CW pipe formation, the entire steel pipe is heated, not just the edges as in ERW pipe. During a process called annealing, the manufacturers heat and slowly cool the steel to reduce its brittleness. When the steel reaches 2,450° F, it is rolled into a cylindrical shape and the edges are fused together through pressure and heat. During the ERW process, the edges of the steel are heated to 2,600° F by revolving copper discs (that serve as electrodes) and fused together.

For SureThreadTM, the result is a stronger, more ductile pipe with a smooth weld seam and uniform grain pattern throughout the entire pipe. Import ERW pipe, on the other hand, is harder and more brittle with: irregular grain patterns, a bump at the weld seam, and a weld seam with different metal properties that the rest of the pipe.

For contractors using standard pipe, the difference really is in the quality of pipe used. According to a survey, 70% prefer working with SureThread over import ERW pipe.

Rockwell Hardness Analysis

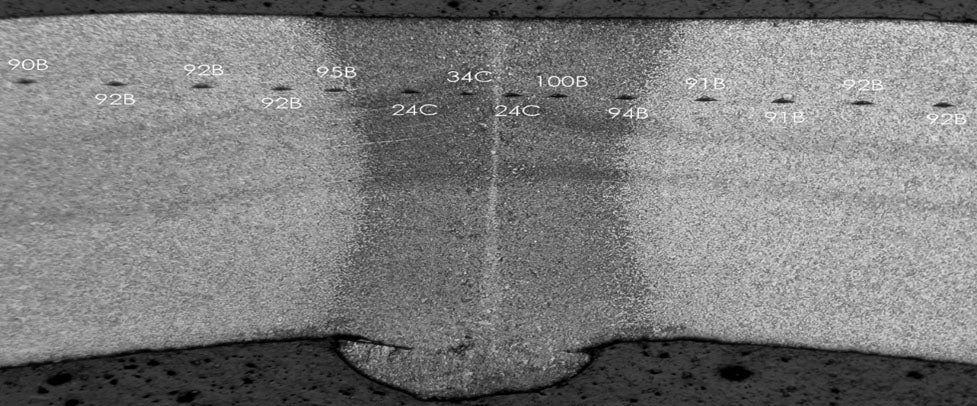

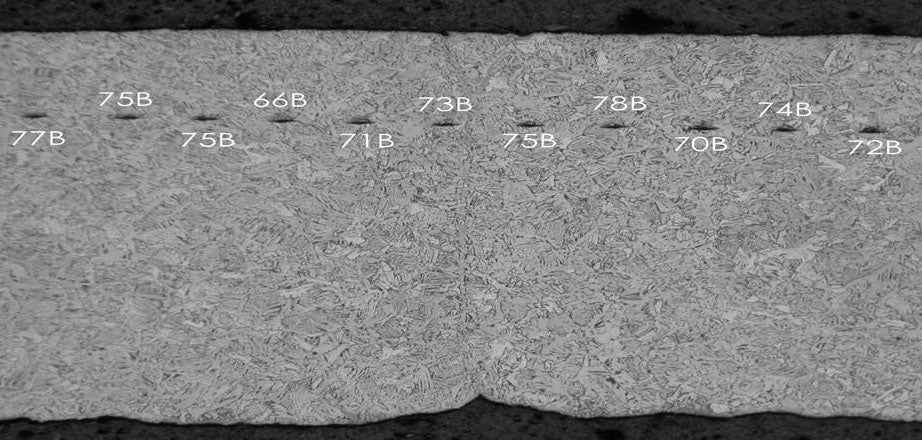

In a Rockwell Hardness analysis completed at our Quality Assurance lab in Chicago, we tested the difference between our SureThreadTM pipe and import ERW pipe. Here are the results:

Import ERW Pipe (from Turkey)

As you can see in the image above, the weld seam in this 1 ½” standard pipe is harder than the body, and there is corrosion and deflection at the ID bead. This makes for a hard seam and difficulty threading the pipe, which often results in unnecessary wear and tear on your tools.

SureThreadTM CW Pipe

For the test, a 2” sample of the A53 CW Type F Grade A pipe was used. As you can see, there is uniform chemistry throughout the pipe due to the full body annealing process. Where the weld was obvious in the import ERW pipe, the weld becomes part of the pipe and is barely noticeable.

So what does this all mean?

For contractors, using SureThreadTM pipe means using high quality pipe that won’t tear up your threaders and dies, costing you time and money. It also means you’ll have an easier time bending, cutting and threading the pipe.

When you’re working on a job, the last thing you want to do is worry about the quality of the products you’re using. When you choose Wheatland, you choose quality.

To learn more about SureThreadTM ASTM A53 Type F Grade A pipe, download our data sheet:

Know better. Know Wheatland.

Tags: CW Pipe, Import ERW Pipe, Standard Pipe, SureThread